How Smart Valves Reduce Irrigation Maintenance Costs

There are two kinds of irrigation maintenance costs on the farm: the kind you see and the kind you don’t.

The ones you can see are typically line items on your budget. Direct costs, like parts and labor.

The ones you don’t see are hidden in the revenue you miss out on from having a poorly performing irrigation system. Hits to quality and yield that come from things like having poor distribution uniformity, lacking a clear line of sight into how much water is really flowing through your system, and being unable to get enough water down ahead of heat events due to an underpowered pump or clogged emitters.

In the past, growers haven’t been armed with the right data to reduce irrigation maintenance costs and make informed decisions.

Without knowing the real-time health and performance of their irrigation system, historically vineyard managers have been forced to spend their maintenance dollars in less than ideal ways.

You either have to do maintenance on a set schedule, regardless of whether it needs to get done, or you simply wait until something breaks.

The problem is that neither approach minimizes the impact to your bottom line. Set schedules can either be way too often, or not nearly often enough. And waiting for something to break almost always leads to downtime at the worst time, like on the hottest days of the year, which can lead to your crop outcomes taking a huge hit.

A couple quick examples.

One common example of a set schedule is waiting 25 or 30 years to replace emitters. With Lumo smart valves, we’ve helped growers identify blocks that were getting twice as much water as they thought due to old, worn out emitters.

Or take something as simple as a clogged filter. We’ve seen instances where a clogged filter reduced flow rates by over 50%! And maybe someone would’ve eventually thought to check the filter, or maybe they have a habit of flushing it every couple weeks, but neither approach works as well as catching the clog in real-time using flow data.

Or take the example of a vineyard manager trying to make the case for a bigger pump. Without having flow rate data from each of their blocks, it’s tough to make the case. A new pump is a big investment. But when a grower can show that they’re unable to hit their target rates, or that they’re consistently unable to get enough water down ahead of heat events, suddenly the case becomes more clear. You can make those invisible costs (hits to crop quality and yield) more tangible and concrete to upper management.

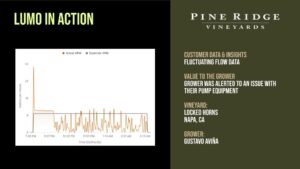

The chart above shows flow rates fluctuating up and down because of a pump in need of maintenance.

In all of these instances, a better understanding of the real-time performance of your irrigation system gives you the ability to take corrective action and to spend your maintenance dollars in a more optimal way, reducing both the visible costs and the hidden ones.

Data driven maintenance saves you money, protects your infrastructure, and improves your crop outcomes.

In the end, irrigation system maintenance is about ensuring your blocks are consistently getting the right amount of water.

To begin optimizing your maintenance spending, you need to have block-level visibility into the real-time performance of your system. That’s what smart valves give you.

Once you can see flow rates and volumes for all your blocks, you can set a baseline expectation of how your system performs and can start to track when your system’s performance is declining.

As your system’s performance declines, you can adjust how long you run your irrigations to ensure you’re still delivering your planned amounts (this is something the Lumo system helps you do automatically through volume-based scheduling).

This reduces the hidden costs of maintenance—you avoid having worse crop outcomes because your crops weren’t receiving the correct amount of water.

Meanwhile, because you’re able to see declines in performance in real time, you can prioritize your maintenance accordingly.

You can flush filters as soon as they need to be flushed and only when they need to be flushed. You can catch leaks and clogs automatically (without needing to send someone to walk the lines looking for leaks), and before they cause crop or infrastructure damage. And you can make upgrades to your system based on hard data and whether or not you’re able to consistently achieve your desired levels of performance.

With greater visibility into the health and performance of your system, you gain more control. You can take corrective action and better prioritize your maintenance efforts. In the end, you’re able to consistently maintain a higher level of irrigation precision and produce superior crop outcomes as a result.

That’s how smart valves help reduce your irrigation maintenance costs. They give you a better, faster, more data-driven way to maintain the health and performance of your system.

If you want to learn more about how Lumo smart valves can reduce irrigation maintenance costs, improve efficiency, and help you achieve higher levels of precision, contact [email protected] or request a demo.