Closing The Irrigation Execution Gap: Lessons From Analyzing 4,500 Irrigations Last Season

For growers today, a gap exists between the volume of water they would ideally like to apply to their crop and the volume they’re consistently delivering in the field.

This is the Irrigation Execution Gap.

And the best growers in the world today are investing in closing the gap to improve crop outcomes, efficiency, sustainability and profitability.

Flow Data Analysis of 4,500 Irrigations From Last Season

Because Lumo smart valves come equipped with built-in flow meters, and because we’re already working with nearly a hundred California vineyards, we’re able to put some numbers around the size of the Irrigation Execution Gap.

After analyzing over 4,500 irrigations from last season, we saw that nearly half were either over or under the intended volume by 10% or more.

Leaks, breaks, chewed-on emitters, clogged filters, blown out risers, pressure losses, pump failures—these things happen all the time.

And their impact isn’t small or insignificant. Irrigation systems routinely experience large variations in performance.

Once you have real-time visibility into flow rates, this fact becomes plain as day.

But that doesn’t mean that nothing can be done.

The other notable finding from analyzing last year’s data was that the percentage of irrigations that missed by 10% or more went down over the course of the season.

Closer to the beginning, it was over three quarters of the time. Toward the end, it was down to just 15%.

Because once you have the ability to calibrate your system in real-time, you can take corrective action and begin to dial in your irrigation precision.

Causes

Vineyard managers are unable to deliver precise volumes of water to every block because they’re limited by their irrigation infrastructure, by how many hours they have in the day, and by their fundamental lack of visibility into the problem.

In other words, they must contend with:

- Irrigation infrastructure issues and limitations

- Labor constraints and manual errors

- A lack of real-time visibility into system performance, including block-level flow and pressure data

It’s a frustrating place to be because every grower knows it’s hurting their ability to grow high-quality grapes at optimal yields and to be as efficient as possible with the water and labor resources they have available.

Examples

A ball valve gets left closed and a block receives no water.

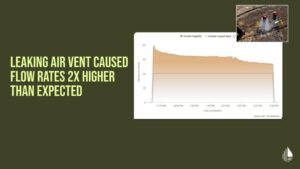

A leaking air vent goes unnoticed wasting gallons of water.

An irrigator runs an irrigation for two hours longer than they meant to because they got caught up doing something else. Or they cut it short because they’re done for the day.

An irrigator turns the water on before they leave for the night at 4pm and shuts it off in the morning at 7am. But due to the water-holding capacity of the soil and the root depth of the vines, the ground and the plants can really only make use of eight hours of water, not fifteen. And the electric pump ends up running through peak electricity rate hours, unnecessarily increasing pumping costs.

A vineyard manager knows a heat spike is coming on Saturday, but it’s already Thursday morning and they know that with the size of their pump, and the time they have in the day, there’s no way in hell they’re going to get enough water down on all of their blocks and avoid taking a hit to crop quality and yield.

With a lack of visibility into flow rates and pressure, a lead irrigator is unable to optimize their set planning and occasionally runs blocks together that achieve lower than expected flow rates. But water still drips from the emitters, so the issue goes undetected indefinitely.

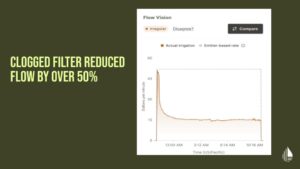

With no way to calibrate the irrigation system in real-time, a fertigation clogs a filter and a block gets half as much water as intended until the filter finally gets flushed.

A vineyard manager or irrigator assumes their system is delivering at a flow rate that it’s simply not delivering at, either due to clogged emitters, problems with pressure, or aging infrastructure more generally. But with no real-time visibility, they’re simply unable to update or adjust their expectations and their crops get consistently over or underwatered as a result.

The list goes on and on.

Anyone with hands-on irrigation experience knows in their bones that this gap exists. It keeps them up at night. Every grower we’ve ever spoken to has said they wish they had better visibility and greater accountability. A way to quantify the problems and take corrective action.

We hear these stories every single day.

Costs

The Execution Gap hurts crop and business outcomes, including:

- Wasted time, effort and water

- Lower labor productivity and water efficiency

- More fuel burned

- Increased pumping costs

- Worse crop outcomes than could’ve otherwise been achieved

When a grower can’t get the right volumes on the right blocks at the right times, they’re not able to grow the best possible crops or work as efficiently as possible. The Execution Gap raises costs and caps revenue potential.

How to Close the Irrigation Execution Gap

With Lumo, growers are able to take steps toward closing the Execution Gap and delivering water with block-level precision.

That starts, first and foremost, with setting a more accurate baseline of your system’s actual performance in the field.

Knowing exactly how many gallons of water your infrastructure is delivering to each block allows you to make immediate improvements. You can quantify known problems. Some blocks might be receiving half or twice as much water as you first suspected because of clogged or worn emitters. Bringing these problems to light allows you to either perform maintenance, or to adjust your irrigation schedule accordingly until the issue can be fixed.

Over time, growers are able to dial in their precision because their expectations of their system’s performance become more accurate, because they’re able to perform data-driven maintenance, and because they’re able to catch issues and calibrate their system in real time. Rather than issues going undetected for days or weeks or months at a time, they’re caught almost instantly.

Because Lumo smart valves come with built-in flow meters, growers are also able to schedule based on volume, rather than relying on rough durations, removing all the guesswork.

And furthermore, because Lumo allows growers to automate their irrigations and schedule them for any time of the day or night, they’re able to avoid peak electricity rate hours and irrigate overnight. Plus they can end the irrigation whenever they want to, rather than relying on an irrigator to close the valves in the morning and being forced to irrigate for far longer than they might need to.

With Lumo, the labor constraints and manual errors go away. Growers gain real-time visibility into the health and performance of their system. And they’re able to deal with precise, verifiable volumes, rather than making guesses or assumptions about the volume of water that’s actually getting delivered to each block.

An Ongoing Process

What we’ve learned from working with growers in the field is that closing the Irrigation Execution Gap is a journey, not a destination.

A system’s performance is never going to be perfect and issues are going to continually arise. Dialling in precision is always a work in progress.

But the best growers in the world are investing in closing the gap because they know the juice is worth the squeeze. With greater precision and more reliable execution, you can grow better grapes at a lower cost with less wasted water.

If you can close the Irrigation Execution Gap, you can run a better business and deliver better crop outcomes.

If you're interested in learning more about how you can close the gap and dial in your own irrigation execution, you can request a demo or register to attend an upcoming WIN webinar we're hosting on April 3rd.