Irrigation Precision + Performance

Lumo Helps Growers Irrigate to Plan with Precision, Control and Efficiency

Learn More

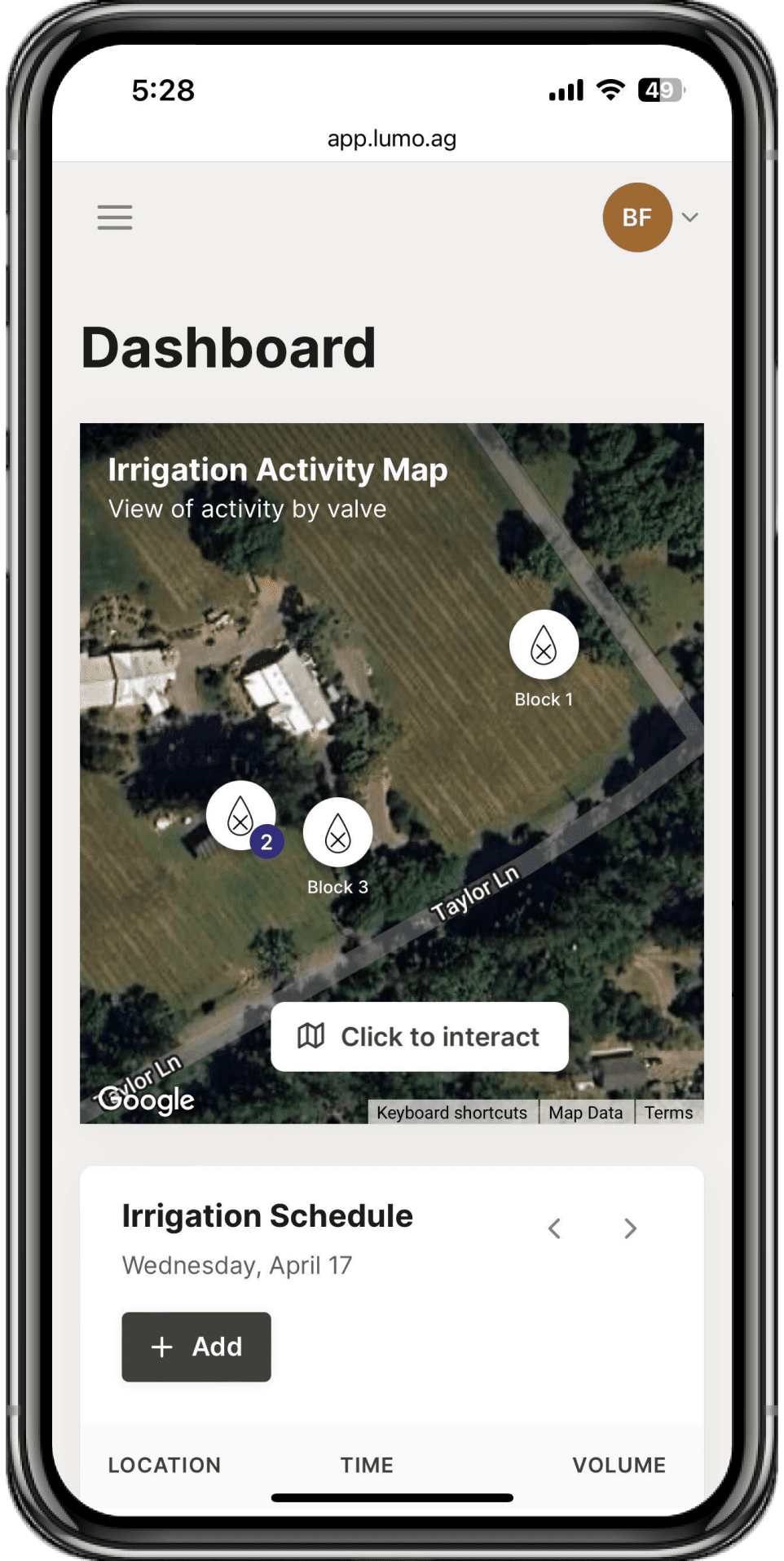

are your blocks receiving the right amount of water?

With Lumo’s block-level data, you’re never left wondering or worried.

Growers today lack the visibility and control necessary to achieve block-level precision. There’s a gap between the volume of water they would ideally like to apply and the volume they actually deliver in the field. This is the Irrigation Execution Gap and it’s bad for business. With block-level data and accountable automation, the best growers in the world today are using Lumo to close their gap, dial in their precision, and finally irrigate to plan.

“There’s a night and day difference from the other irrigation automation systems we’re working with. It’s everything everyone else says they can do but Lumo actually does it.”

Tyler Klick, Partner and Viticulturist at Redwood Empire Vineyard Management

Precision Irrigation Improves Crop and Business Outcomes

up to

90

%

less time spent irrigating

up to

30

%

reduction in pumping costs

up to

20

%

increase in crop quality

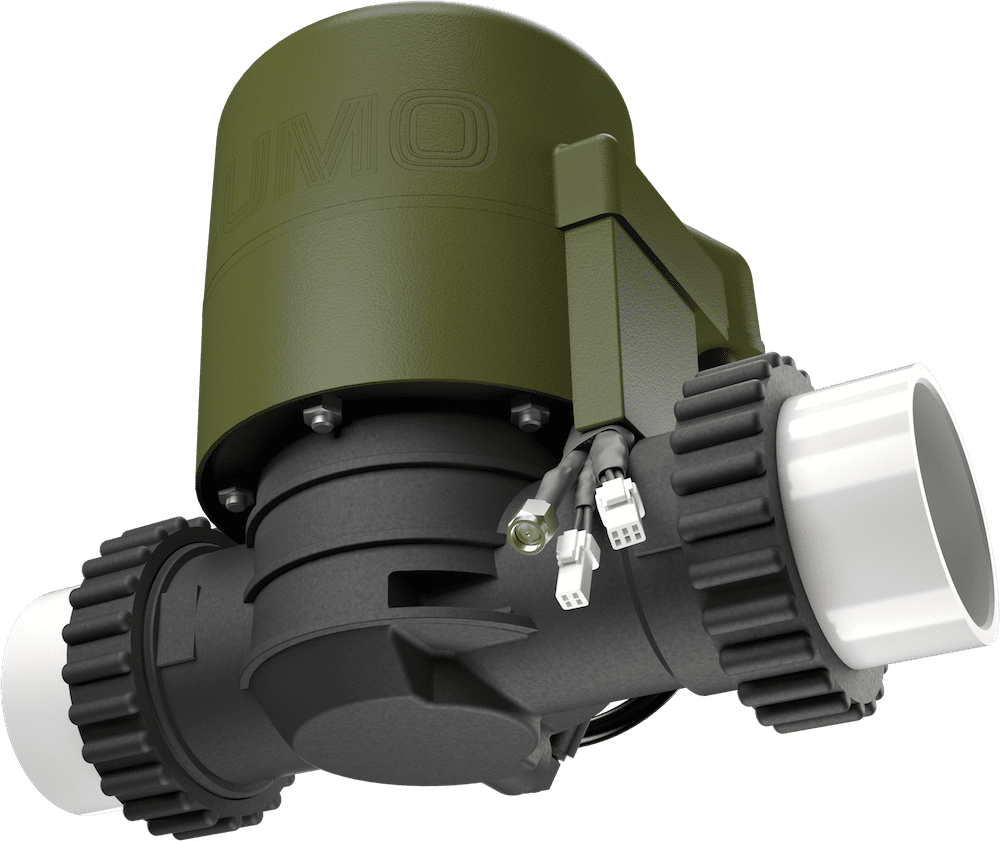

Built-in accountability

Lumo was built from the ground up to meet the needs of the modern grower. Growers want to irrigate with precision, but they also need a system that’s simple to install, intuitive to use, and easy to maintain. A way to not only automate the turning of valves, but also get the data necessary to operate with accountability and peace of mind.

REQUEST A DEMO

Results from the field

The Benefits of Precision Irrigation

Higher Yields

Precision irrigation improves yields by allowing growers to fine-tune vine stress, optimize water delivery, maintain soil moisture levels, and achieve high distribution uniformity (DU) across irrigation blocks.

Reduced Yield Loss and Damage

Precision irrigation systems give growers 24/7 remote control and monitoring over their irrigations, allowing them to eliminate overwatering or underwatering, and react instantly to heat events to prevent crop loss or damage.

Improved Sustainability

Precision irrigation improves sustainability by reducing wasted water, improving energy efficiency by irrigating at off-peak times, and cutting back emissions from vehicles used to irrigate manually.

Greater Labor Efficiency

Precision irrigation systems improve operational efficiency through the automation of manual tasks like turning valves and looking for leaks, reducing errors and minimizing the need for on-site monitoring and reporting.